SIMATIC S7-300

Exploring the SIMATIC S7-300: A Comprehensive Guide for Automation Professionals

At Rudra Power & Automation, we are aware that industrial process optimisation requires dependable automation systems. Siemens’ SIMATIC S7-300 is one of the industry’s top solutions in this field. For numerous sectors, this adaptable and modular programmable logic controller (PLC) has been a key component of automation technology. We will explore the SIMATIC S7-300’s features, parts, uses, and benefits in this post to help you see why automation experts have chosen it.

What is the SIMATIC S7-300?

A reliable and scalable PLC system, the SIMATIC S7-300 is made for a range of automation applications. The S7-300 is renowned for its exceptional performance and dependability, meeting both basic control procedures and intricate automation needs. It may be customised thanks to its modular construction, which makes it appropriate for a wide range of applications in several industries, such as building automation, process control, and manufacturing.

Key Features of the SIMATIC S7-300

1. Modular Design:

The S7-300’s modular architecture allows customers to customise the system to meet their own requirements. Combining several CPUs, I/O modules, and communication processors makes it simple to scale as your needs evolve.

2. High Performance:

A variety of CPUs with different processing rates and features are available in the S7-300. Because of its adaptability, the system can effectively manage both simple and complicated tasks, giving demanding applications the performance they require.

3. Comprehensive Communication Options:

The S7-300’s capacity to interact via a variety of protocols, such as Ethernet, Profibus, and Profinet, is one of its most notable characteristics. This feature improves data exchange and operational efficiency by enabling smooth integration with other networks, systems, and devices.

4. User-Friendly Programming Environment:

Siemens’ TIA Portal and STEP 7 software make it simple to program the S7-300. Even for people without a lot of programming knowledge, these tools’ user-friendly interfaces make it simple to create, test, and maintain programs.

5. Advanced Diagnostic Functions:

The S7-300 has sophisticated diagnostic features that aid in the prompt identification of defects and system problems. In industrial environments, this capability is essential for reducing downtime and guaranteeing continuous operation.

Components of the SIMATIC S7-300

The S7-300 system is made up of a number of essential parts that combine to offer a comprehensive automation solution:

1. Central Processing Unit (CPU):

The central processing unit (CPU) of the S7-300 system is in charge of processing input/output signals and carrying out control programmes. Siemens provides a range of CPUs to satisfy various performance requirements, along with redundancy options to improve dependability.

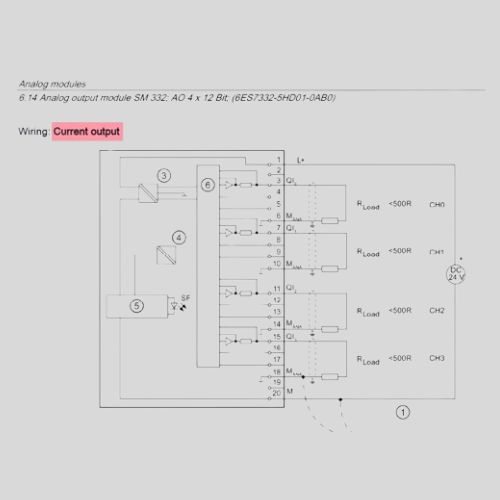

2. Input/Output (I/O) Modules:

Field devices like sensors and actuators can communicate with the PLC more easily thanks to I/O modules. Depending on the kind of signals being processed, they can be either digital or analogue. Because of its adaptability, users can modify the system to meet the needs of different applications.

3. Communication Processors:

The S7-300 can communicate with various systems and devices thanks to these modules. The S7-300 can easily integrate into current networks by supporting a variety of communication protocols, improving connectivity and data flow.

4. Power Supply:

By giving the components the required voltage and current, the power supply module makes sure that the complete system runs dependably.

5. Expansion Modules:

To improve functionality or boost the system’s I/O capacity, users can add expansion modules. One important advantage is its modularity, which enables customised systems that can expand to meet changing business requirements.

Applications of the SIMATIC S7-300

The SIMATIC S7-300’s adaptability enables it to be used in a variety of applications, such as:

1. Manufacturing Automation:

Production lines, assembly procedures, and machinery are all heavily controlled by the S7-300 in manufacturing settings. It is perfect for automating repeated processes because of its capacity to manage intricate sequences and interlocks.

2. Process Control:

The S7-300 monitors and regulates a number of factors in sectors like food manufacturing, water treatment, and chemical processing to guarantee peak performance and adherence to safety regulations.

3. Building Automation:

Additionally, the system is used to handle lighting, security, HVAC, and building automation. Its sophisticated communication features make it easier to integrate different construction systems.

4. Packaging:

The S7-300 works well in automated packing lines, where it aids in process control to improve accuracy and speed.

Benefits of Using the SIMATIC S7-300

- Flexibility and Scalability: The S7-300’s modular design makes it simple to expand and customise, making it appropriate for projects of any scale. The system can be modified as your needs change without needing to be completely redone.

- Reliability: The S7-300 demonstrates Siemens’ reputation for excellent engineering. This PLC reduces the chance of malfunctions and downtime with its sturdy design and sophisticated diagnostic capabilities.

- Increased Productivity: The S7-300 contributes to improved operational efficiency, which raises productivity and lowers operating expenses by automating procedures and offering accurate control.

- Smooth Integration: Better data exchange and operational coordination are made possible by the S7-300’s easy integration with current systems and devices thanks to its many connectivity possibilities.

- Future-Proofing: The S7-300 is still a viable option for contemporary automation requirements thanks to Siemens’ continuous support and updates, guaranteeing that your investment will continue to yield returns over time.

A unique PLC in the field of industrial automation, the SIMATIC S7-300 is strong and adaptable. It is a popular option for companies wishing to improve their automation processes because of its modular design, excellent performance, and wide range of application capabilities. Our goal at Rudra Power & Automation is to assist you in utilising the S7-300 to its maximum capacity in your business processes.

Do not hesitate to contact us if you have any concerns concerning the SIMATIC S7-300’s implementation or optimisation in your automation projects. Our team of professionals is available to offer direction and assistance, guaranteeing the smooth and effective operation of your systems. Together, let us accomplish your automation objectives!