SIMATIC S7-1500

Unlocking Advanced Industrial Automation with the Siemens SIMATIC S7-1500

Efficiency, dependability, and scalability are critical factors in the field of industrial automation. Siemens, a leader in automation technology worldwide, provides strong solutions to meet the various demands of contemporary industries. The SIMATIC S7-1500 PLC (Programmable Logic Controller) is one of its most sophisticated and feature-rich products; it has established itself as a standard for automation performance and adaptability.

At Rudra Power & Automation, we are committed to giving our customers state-of-the-art equipment to maximize their productivity. Businesses in sectors including manufacturing, energy, and process control can benefit greatly from the SIMATIC S7-1500. The main characteristics, advantages, and uses of the SIMATIC S7-1500 will be discussed in this article, along with how it may promote automation excellence across a range of industries.

What is the SIMATIC S7-1500?

A sophisticated PLC that is a member of the Siemens S7 PLC series is the Siemens SIMATIC S7-1500. The S7-1500 has a high degree of scalability, flexible communication, and strong processing capabilities, making it ideal for handling complicated automation jobs. It is perfect for large-scale operations that need real-time control and high-speed data processing because it is designed to satisfy the demands of demanding industrial applications.

The S7-1500 is a complete solution for a variety of automation problems since it combines motion control, safety, and communication features. It is especially well-suited for sectors including material handling, energy generation, food processing, and automobile manufacture where accuracy, safety, and efficiency are crucial.

Key Features of the SIMATIC S7-1500

High Performance and Speed:

The SIMATIC S7-1500 is equipped with strong CPUs that can process complicated automation jobs quickly. Real-time data is processed effectively by the high-performance processors, which makes it perfect for applications that require quick response times and quick decisions.

Integrated Safety Functions:

The S7-1500’s integrated safety functionality is one of its best qualities. It enables users to put safety-related control procedures into place, guaranteeing the security of both workers and equipment. The machinery directive and functional safety regulations, as well as other international safety standards, are met in part by this feature.

Advanced Communication Capabilities:

Several communication protocols, such as PROFINET, Ethernet/IP, Profibus, and Modbus TCP/IP, are supported by the S7-1500. It is a flexible and future-proof solution for enterprises moving to Industry 4.0 and IoT settings because it enables smooth integration with other devices, systems, and networks.

Scalability and Flexibility:

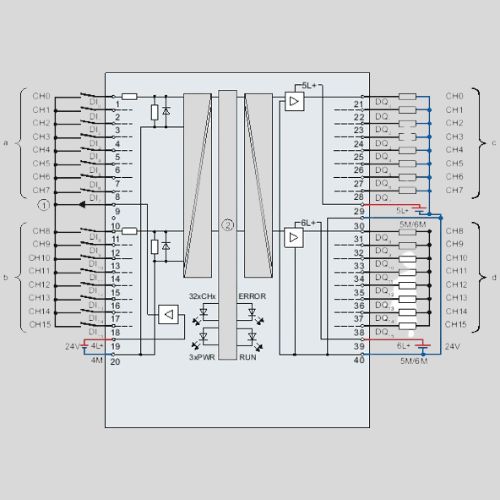

The S7-1500 is very expandable due to its modular design. Without requiring total system redesigns, it enables companies to increase their automation systems in tandem with their operations. The PLC is adaptable to a variety of applications since it supports a large number of I/O modules.

Integrated Motion Control:

The S7-1500 has integrated motion control functionality for applications that need precise control of robotics, motors, or other moving elements. Because of this capability, it is the perfect option for sectors like packaging and automotive manufacture, where precise placement and quick operations are essential.

User-Friendly TIA Portal Software:

Siemens’ Totally Integrated Automation (TIA) Portal is used to program the S7-1500. This software suite offers a user-friendly interface that boosts productivity while streamlining system programming, configuration, and diagnostics. Engineers can work with their preferred approach thanks to the TIA Portal’s support for multiple programming languages, including Structured Text (ST), Function Block Diagram (FBD), and Ladder Logic (LAD).

High Availability and Redundancy:

The S7-1500 provides high availability setups with redundant CPUs and power sources to guarantee optimal uptime. This functionality is perfect for industries that cannot afford downtime since it guarantees that crucial operations continue to function normally even in the case of hardware problems.

Advantages of the SIMATIC S7-1500

Increased Productivity:

Industries may greatly boost their productivity by using the S7-1500 to automate procedures. Faster decision-making and real-time control are made possible by the PLC’s high computing power, which results in improved workflows and shorter cycle times.

Cost Efficiency:

Advanced automation technology can save a lot of money over time, even though the initial expenditure may appear exorbitant. Through enhanced process efficiency, lower maintenance requirements, and energy optimization, the S7-1500 lowers operating expenses.

Enhanced Process Control:

From assembly lines to chemical reactions, the S7-1500’s sophisticated capabilities enables precise control of manufacturing operations. This lowers waste, improves overall efficiency, and guarantees constant product quality.

Improved Safety Standards:

The S7-1500’s built-in safety features contribute to adherence to global safety regulations. In addition to safeguarding workers, this also stops possible harm to infrastructure and machines.

Seamless Integration with IoT and Industry 4.0:

The S7-1500 is made to easily integrate with Internet of Things (IoT) systems as industries adopt Industry 4.0 more and more. This makes it possible for companies to use real-time data for process optimization, remote monitoring, and predictive maintenance, which results in more intelligent, data-driven decision-making.

Applications of the SIMATIC S7-1500

Numerous sectors make use of the SIMATIC S7-1500 because it is adaptable and scalable to meet various automation requirements. Here are a few important uses:

Manufacturing Automation:

When it comes to automating manufacturing operations like assembly lines, robotic systems, and CNC machines, the S7-1500 is an excellent choice. It is perfect for streamlining manufacturing lines and increasing throughput because of its quick processing speed, integrated motion control, and modular architecture.

Process Automation:

The S7-1500 regulates vital operations including mixing, temperature control, and packaging in process sectors like chemical, pharmaceutical, and food production. It guarantees that all procedures are completed effectively and safely while adhering to strict industry requirements.

Energy Management:

In the generation and distribution of energy, the S7-1500 is essential. It is employed for grid monitoring, power plant control, and the integration of renewable energy sources into the current infrastructure. Maintaining uptime in vital energy applications requires its redundancy and high availability features.

Water Treatment and Infrastructure:

The S7-1500 is frequently used in water treatment facilities to regulate filtration systems, pumps, and valves. Its accurate control features guarantee the preservation of water purity, and real-time monitoring provide the information required to maximize plant performance.

Automotive Industry:

The S7-1500 is utilized in the automotive sector to manage robotic arms, manufacturing lines, and quality assurance procedures. It is the perfect option for handling the intricate duties required in the production of automobiles because of its built-in motion control, quick processing rates, and scalability.

A high-performance, scalable, and adaptable PLC, the Siemens SIMATIC S7-1500 provides sophisticated automation capabilities to industries across the globe. Whether you work in manufacturing, energy management, process control, or another industrial field, the S7-1500 offers the strength, accuracy, and dependability you need to remain competitive.

Our goal at Rudra Power & Automation is to assist companies in utilizing the newest automation technology, such as the SIMATIC S7-1500, to streamline processes and boost productivity. It is an essential tool for enterprises looking to improve their automation systems because of its cutting-edge characteristics, which include high processing speed, sophisticated communication protocols, and integrated motion control.

The SIMATIC S7-1500 is the answer you need if you want to enhance your manufacturing procedures, cut expenses, and increase output. To find out more about how the SIMATIC S7-1500 may improve your automation systems and streamline your operations, get in touch with us right now.