Programmable Logic Controllers (PLC)

Unleashing Industrial Automation with Programmable Logic Controllers (PLC)

Programmable logic controllers (PLCs) have become a game-changer in the rapidly developing field of industrial automation, transforming company operations and streamlining procedures in a variety of industries. At Rudra Power & Automation, we take pleasure in providing state-of-the-art PLC solutions that are customised to our clients’ specific requirements, allowing them to reach previously unheard-of levels of productivity, efficiency, and accuracy.

An industrial digital computer called a programmable logic controller (PLC) is used to automate and manage a range of production lines, machinery, and manufacturing processes. PLCs provide unmatched flexibility in contrast to older control systems, making it simple to reprogramme and adjust to shifting production needs.

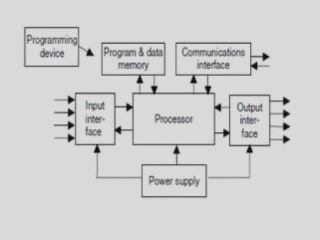

A central processing unit (CPU), memory, input/output (I/O) modules, and a programming device are some of the essential parts of a PLC. Together, these parts function flawlessly to carry out user-specified commands, keep an eye on and manage a variety of gadgets and sensors, and guarantee effective and seamless operations.

Benefits of Implementing Programmable Logic Controllers

Enhanced efficiency and productivity:

PLCs greatly increase productivity and efficiency by automating crucial operations and reducing the need for human intervention. This leads to higher production and lower operating expenses.

Improved Quality Control:

PLCs provide constant and dependable product quality by reducing waste and faults through precise control capabilities, which ultimately raises customer satisfaction.

Flexible and Scalable:

PLCs are extremely adaptable to a wide range of applications and scalable for future expansion since they are easily reprogrammable to accommodate changing production requirements.

Increased Safety:

PLCs make workplaces safer by automating potentially dangerous operations and adding strong safety features. This lowers the chance of accidents and guarantees adherence to industry rules.

Real-time Monitoring and Control:

PLCs make it possible to monitor and control a variety of processes in real time, making it possible to make quick modifications and improvements that enhance system performance as a whole.

Applications of Programmable Logic Controllers

Industrial Automation:

- Manufacturing: In charge of packing machines, assembly lines, and other machinery used in production.

- Process control: the management of flow rate, temperature, pressure, and other process variables in the food, beverage, and chemical industries.

- Machine Tools: Using CNC (computer numerical control) equipment to perform accurate fabrication and machining.

Building Automation:

- HVAC Systems: Managing air conditioning, heating, and ventilation for comfort and energy economy.

- Lighting control: The management of lighting systems for security and energy efficiency.

- Access Control: Controlling access to buildings and restricted areas.

Transportation:

- Traffic signals: Managing the flow of vehicles and averting gridlock.

- Railroad signalling: guaranteeing effective and safe train operations.

- Vehicle Control: Putting modern driver aid features and driverless car technologies into practice.

Renewable Energy:

- Solar Power Systems: Controlling energy storage and solar panel arrays.

- Wind Power Systems: Grid integration and wind turbine control.

Robotics:

- Industrial robots: Managing the motions of robotic arms to perform activities such as material handling, welding, and assembly.

- Service Robotics: Controlling robots utilized in the hospitality, healthcare, and other service sectors.

Water and Wastewater Treatment:

- Process Control: Enforcing safe drinking water by controlling the water treatment procedures.

- Wastewater Treatment: Environmental protection through management of wastewater treatment facilities.

Consumer Electronics:

- Appliances: Including sophisticated control mechanisms in appliances such as ovens, refrigerators, and washing machines.

- Home automation: Managing different home systems, such as the entertainment, security, and lighting systems.