Motor Protection Circuit Breakers (MPCBs)

Motor Protection Circuit Breaker: Essential Guide for Reliable Motor Safety

Electric motors are essential parts that power machinery and equipment in commercial and industrial settings. Motors are susceptible to a number of electrical issues, though, which can result in costly repairs, system failures, and downtime. Using Motor Protection Circuit Breakers (MPCBs) is one of the best solutions to safeguard motors from such risks.

We at Rudra Power & Automation are aware of how critical motor protection is to preserving operating effectiveness. The functions, advantages, and uses of motor protection circuit breakers in contemporary industrial settings will all be covered in detail in this article.

What is a Motor Protection Circuit Breaker (MPCB)?

In industrial and commercial environments, electric motors are integral components that drive machinery and equipment. However, motors are prone to various electrical faults, which can lead to system failures, downtime, and even expensive repairs. One of the most effective ways to protect motors from such hazards is by using Motor Protection Circuit Breakers (MPCBs).

At Rudra Power & Automation, we understand the importance of motor protection for maintaining operational efficiency. This article will provide an in-depth look into Motor Protection Circuit Breakers, including how they work, their benefits, and their applications in modern industrial setups.

Motor Protection Circuit Breakers (MPCBs) Brand

- ABB

- Fuji

- Eaton

- Hager

- Larsen & Toubro (L&T)

- Schneider

- Siemens

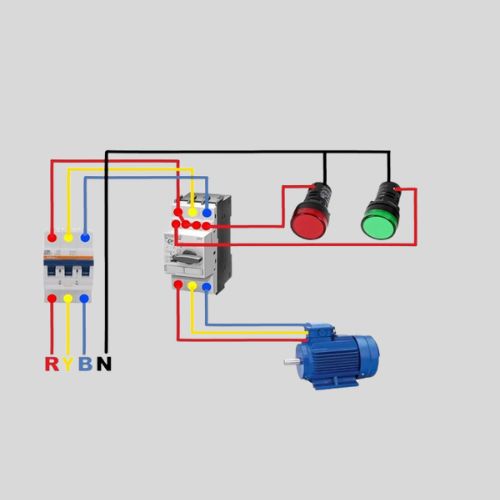

How Does a Motor Protection Circuit Breaker Work?

MPCBs keep an eye on electrical changes in the circuit that is connected to the motor and react accordingly. Usually, they are made to respond to the following circumstances:

Overload Protection:

To avoid overheating and insulation damage, the MPCB will detect an overload and cut off the power supply if a motor draws excessive current for an extended amount of time.

Short Circuit Protection:

A short circuit might result in an abrupt spike in current that can seriously harm the motor right away. To reduce the chance of equipment failure, the MPCB is made to swiftly identify such surges and cut the motor off from the power source.

Phase imbalance or phase loss:

Phase imbalances or even phase loss can occur in three-phase motors, leading to inefficient performance or even motor burnout. MPCBs are able to identify phase failure and prevent the motor from running in such unfavourable circumstances.

Under-voltage and Over-voltage Protection:

Additionally, MPCBs can shield motors from variations in voltage. Motors may operate inefficiently in an undervoltage situation and sustain damage in an overvoltage situation. MPCBs keep an eye on the voltage and activate the appropriate protection systems.

Key Features of Motor Protection Circuit Breakers

In order to improve motor safety and guarantee smooth operations, motor protection circuit breakers provide a number of characteristics. Here are a few of the salient features:

- Adjustable Trip Settings: Using MPCBs, you can establish particular trip thresholds that are determined by the rated current of the motor. This increases protection effectiveness and guarantees that the motor runs within safe bounds.

- Thermal and Magnetic Protection: MPCBs usually provide both magnetic and thermal protection. Magnetic protection reacts to current surges and short circuits, whereas thermal protection guards against overloads.

- Compact Design: Because MPCBs are small and take up little room, they can be installed in electrical panels or motor control centres (MCCs).

- Manual and automatic reset: These are available on many MPCBs, giving operators the choice to manually reset the breaker or have it reset automatically after the problem has been fixed.

- Broad Range of Current Ratings: MPCBs can be used in a variety of motor types and applications, ranging from small appliances to huge industrial equipment, because they come in a wide range of current ratings.

- Integrated Contactors: To improve protection and operational control, certain MPCBs have integrated contactors that regulate the motor’s start and stop functions.

Why is motor protection important?

When a single motor fails in an industrial setup, the entire production process might be disrupted, resulting in expensive downtime and repair costs. Here are some reasons why motor protection is essential, especially when MPCBs are used:

- Prevent Equipment Damage: By protecting motors against excessive current, voltage swings, and other electrical problems, MPCBs help to avoid expensive damage to machinery and equipment.

- Reduce Downtime: MPCBs help minimise downtime and guarantee that production operations can be promptly restored by promptly responding to failures and cutting motors from the electrical supply.

- Boost Safety: Electrical problems with motors can result in hazardous circumstances like electrical shocks or fires. By immediately turning off the motor in the case of an electrical malfunction, MPCBs improve worker safety.

- Increase Motor Lifespan: By guaranteeing that motors always operate in ideal conditions, proper protection using MPCBs helps to increase the operational life of motors.

Types of Motor Protection Circuit Breakers

Based on particular uses, characteristics, and defence mechanisms, MPCBs are classified into different categories. Here are a few typical kinds:

Thermal-Magnetic MPCBs:

These MPCBs offer complete protection by combining magnetic and thermal trip mechanisms. While the magnetic component reacts to short circuits, the thermal component manages overload prevention.

Electronic MPCBs:

These breakers monitor and guard against electrical failures using electronic circuits. They are frequently employed in contemporary industrial applications and provide accurate protection.

Motor Circuit Protector (MCP):

Although they may need independent overload protection, MCPs are specialised circuit breakers that offer high-speed short-circuit protection. In motor control centres, MCPs are frequently utilised in combination with overload relays.

Manual Motor Starters:

These simple MPCBs are used to manually turn on and off motors. They may not have as many sophisticated functions as other MPCB types, but they do offer overload safety.

Applications of Motor Protection Circuit Breakers

Vehicle Safety There are many different industries and uses for circuit breakers. Among the most popular applications are:

- Industrial Automation: MPCBs safeguard the motors that drive pumps, robotic arms, conveyors, and other equipment in automated production facilities.

- HVAC Systems: Compressors, fans, and pumps in HVAC systems frequently depend on motors for operation. MPCBs aid in preventing electrical problems from causing harm to these motors.

- Water Treatment Plants: In order to provide continuous water supply and treatment processes, motors are utilised in water pumps and treatment equipment. These motors are reliably protected by MPCBs.

- Agricultural Equipment: Electrical fault protection is necessary for the motors in feeding systems, irrigation pumps, and other farm equipment. MPCBs are essential in helping these motors last longer.

- Renewable Energy: Motors are frequently utilised in control systems for wind and solar power plants. Variable power generation can result in fluctuating electrical conditions, which MPCBs can shield these motors from.

Choosing the Right Motor Protection Circuit Breaker

The type of motor, its rated power, the operating environment, and any particular protective needs all play a role in choosing the best MPCB. We at Rudra Power & Automation provide a large selection of MPCBs that are suited to various industrial requirements. Our staff can assist you in selecting the best product for your needs.

Important factors to take into account while selecting an MPCB are:

- Rated Current: Verify that the motor’s current rating and the MPCB match.

- Breaking Capacity: The maximum current that the breaker can cut off without causing damage is known as its “breaking capacity.”

- Trip Settings: To accommodate particular motor needs, select MPCBs with programmable trip settings.

Vehicle Safety Circuit breakers are an essential part of improving operational safety, reducing downtime, and protecting motors from electrical problems. Our goal at Rudra Power & Automation is to supply premium MPCBs that provide dependable motor protection for a range of industrial applications.

Purchasing the appropriate motor protection solution will extend the life of your machinery, lower maintenance expenses, and maintain the efficiency of your business. To find out more about our selection of MPCBs and how they may help your company, get in touch with us right now.