Modicon M251 PLC

Modicon M251 PLC: Advanced Industrial Automation with Scalability and Flexibility

Selecting the appropriate Programmable Logic Controller (PLC) is essential in the field of industrial automation to guarantee the seamless and effective functioning of manufacturing processes, production lines, and control systems. For companies looking for a dependable, adaptable, and high-performing solution, Schneider Electric’s Modicon M251 PLC provides a robust automation platform that can handle a variety of industrial requirements. Modern automation solutions are what we offer at Rudra Power & Automation, and the Modicon M251 PLC is a popular option for businesses looking to streamline their operations.

The features, advantages, uses, and reasons why the Modicon M251 PLC is a fantastic option for industrial automation systems will all be covered in detail in this article. The Modicon M251 delivers unparalleled versatility and scalability, whether you’re starting a new automation project or replacing your current control systems.

What is the Modicon M251 PLC?

Schneider Electric is the developer of the small, modular Modicon M251 PLC. It is made for uses that call for sophisticated automation and control, especially in complicated systems, medium-sized machinery, and process automation. The Modicon series from Schneider Electric, which has a long history of dependability and innovation in industrial control systems, includes the M251 PLC.

Because of the M251’s scalability and versatility, organizations can customize the system to meet their unique needs. Its high-performance processing capabilities guarantee seamless and effective operations, and its modular design makes integration with other systems simple. For machine builders, OEMs, and end users who require a robust yet adaptable automation solution, the Modicon M251 is especially well-suited.

Key Features of the Modicon M251 PLC

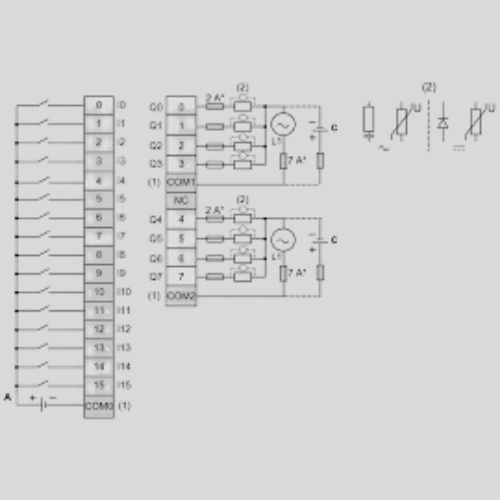

- Modular and Scalable Design: Because of its modular design, the Modicon M251 PLC enables customers to tailor the system to their own requirements. As needed, expansion units, communication modules, and digital and analog I/O modules can be readily added. Because of its adaptability, the system may be scaled up or down, giving organizations the chance to modify their automation configuration as needs change. The Modicon M251’s scalability guarantees that it can manage bigger and more intricate activities in addition to being appropriate for small control systems. This makes it perfect for major businesses that want a high-performance PLC as well as startups searching for an inexpensive alternative.

- Powerful Processing and Performance: With its fast processor, the Modicon M251 PLC can manage a wide range of intricate control duties. It has an ARM-based core CPU, which guarantees great responsiveness and quicker control program execution. This makes it appropriate for uses like motion control, intricate algorithms, and high-speed I/O that require precise control. Real-time applications are also supported by the M251’s increased processing capability, which guarantees that the PLC can manage taxing jobs like data gathering, machine monitoring, and sensor data processing without experiencing any latency problems.

- Flexible Communication Capabilities: The integration of several devices, sensors, and controllers into a single system in contemporary industrial systems depends heavily on communication. Because of its many connectivity options, the Modicon M251 PLC is quite compatible with current automation solutions. It offers smooth interaction with a range of devices, such as HMI panels, SCADA systems, and remote I/O, by supporting Ethernet/IP, Modbus TCP, Modbus RTU, and CANopen protocols. Because of its adaptability, the Modicon M251 PLC may be quickly and easily incorporated into your facility’s current network infrastructure, which lowers the time and expense involved in system integration. Additionally, its integrated Ethernet connector allows for remote access, monitoring, and troubleshooting, allowing operators to diagnose issues or make modifications from any location in the world.

- EcoStruxure™ Machine Expert Software: Schneider Electric’s user-friendly EcoStruxureTM Machine Expert (previously SoMachine) programming software makes it simple to program and configure the Modicon M251 PLC. Ladder Logic (LD), Structured Text (ST), Function Block Diagram (FBD), and other programming languages are supported by this software, which offers a comprehensive programming environment. Online diagnostics, real-time monitoring, and modeling are additional capabilities of the EcoStruxureTM Machine Expert software that assist cut down on development time and guarantee optimal performance from the PLC system. Downtime during commissioning and operation is greatly decreased since engineers may create, test, and implement control programs with ease and resolve problems remotely.

- Advanced Diagnostics and Maintenance Features: The Modicon M251’s sophisticated monitoring and diagnostic capabilities are among its primary attributes. In order to assist operators in promptly identifying and resolving problems, the system provides real-time diagnostic information about the PLC and linked devices. This lowers the possibility of equipment failure and guarantees that production lines and machinery run continuously. Engineers can diagnose and fix the system remotely thanks to its remote monitoring capabilities, which makes it simpler to resolve problems without having to be physically present. Businesses who operate across many locations or in remote areas will particularly benefit from this feature.

- Energy Efficiency and Environmental Sustainability: Because of its low energy consumption, the Modicon M251 PLC helps organizations save money on running expenses while preserving a high degree of automation and control. As the importance of sustainable practices increases, the M251 PLC assists businesses in optimizing their energy use, which lowers energy costs and lessens their carbon footprint.

- Integration with IoT and Industry 4.0: Manufacturers may use smart technologies in their operations thanks to the Modicon M251 PLC’s complete compatibility with Industry 4.0 and the Internet of Things (IoT). Businesses may increase productivity and efficiency by integrating IoT sensors and devices, optimizing machine performance, and making data-driven choices.

Benefits of the Modicon M251 PLC

Scalable and Customizable:

The Modicon M251 PLC’s modular design enables companies to alter the system to suit their requirements. The M251 is extremely scalable, meaning it can expand with your company thanks to the addition and removal of I/O, connectivity, and extension modules. The M251 can readily adjust to your needs, whether you are managing a large manufacturing line or automating a small procedure.

Faster Time to Market:

Businesses can save development times and speed up time-to-market for new systems and products by utilizing the Modicon M251 PLC’s high-performance processing and user-friendly programming tools. Automation solutions are easy for engineers to set up and implement, reducing downtime and guaranteeing timely and cost-effective project completion.

Reduced Downtime and Increased Productivity:

The Modicon M251 PLC is made to minimize maintenance expenses and increase operational uptime. Businesses can swiftly identify errors and stop problems from getting worse with its sophisticated diagnostic tools and real-time monitoring. Faster troubleshooting, less time spent on repairs, and uninterrupted operations are all made possible with remote access capabilities.

Energy Savings:

The Modicon M251 PLC’s energy-efficient architecture allows it to provide high-performance control while assisting businesses in lowering their electricity usage. It is the perfect option for businesses that care about the environment because lower energy use results in financial savings and encourages sustainable practices.

Future-Proof Solution:

The Modicon M251 PLC offers a future-proof automation solution as companies continue to adopt Industry 4.0 and smart manufacturing technologies. The M251 PLC is well-suited to integrate with new technologies and digital transformation projects because of its Ethernet-based communication capabilities, remote monitoring capabilities, and interoperability with IoT devices.

Applications of the Modicon M251 PLC

Numerous industrial applications can make use of the adaptable Modicon M251 PLC. Among the most typical use cases are:

Machine Automation:

In sectors including robotics, assembly lines, and packaging, the Modicon M251 is perfect for managing automated systems and machinery. It offers manufacturers and machine builders flexible solutions by handling both discrete and process control.

Energy Management:

Smart grid control, building energy management systems (BEMS), and HVAC control are just a few of the energy management applications that the M251 PLC excels at. It is a useful instrument for cutting expenses and enhancing energy efficiency because of its capacity to communicate with energy monitoring systems and optimize energy usage.

Water and Wastewater Treatment:

The M251 PLC regulates dosing stations, filtration systems, pumps, and valves in water treatment facilities. Its dependable performance and remote monitoring features guarantee ongoing operations in crucial applications including stormwater management, wastewater treatment, and water purification.

Food and Beverage Processing:

The M251 PLC automates a number of tasks in the food and beverage sector, including filling, packing, and batching. Because of its adaptability and quick processing, it can operate consistently and dependably, guaranteeing both product quality and legal compliance.

Building Automation:

Lighting, HVAC, access control, and security systems are all frequently managed by the Modicon M251 PLC in building automation systems. It is the perfect option for smart building solutions because of its capacity to interface with other building management systems (BMS).

Why Choose the Modicon M251 PLC?

A very adaptable, scalable, and reasonably priced option for a variety of industrial automation requirements is the Modicon M251 PLC. With its robust processing capabilities, modular architecture, wide range of connectivity choices, and sophisticated diagnostics, the M251 gives companies the means to streamline processes, cut down on downtime, and boost output.

The Modicon M251 PLC is a vital part of Rudra Power & Automation’s offering of premium automation solutions. Get in touch with us right now to find out how the Modicon M251 PLC can enhance your automation procedures and support your company’s continued competitiveness in the fast-paced industrial world of today.