Fuse Unit

Understanding Fuse Units: A Comprehensive Guide for Power and Automation

We at Rudra Power & Automation think that in order to maximise productivity and safety in any industrial setup, a thorough grasp of electrical components is crucial. The fuse unit is one of such essential part. The definition, types, uses, and significance of fuse units in power and automation systems will all be covered in this article.

What is a fuse unit?

An electrical safety device called a fuse unit guards against overcurrent situations in electrical circuits. It serves as a barrier, keeping too much current from destroying machinery and possibly starting fires. The fuse element melts when the current passes through it above its rated capacity, cutting off the circuit and halting the power flow.

Key Components of a Fuse Unit

- The conductor that melts when exposed to too much electricity is known as the fuse element.

- The enclosure that houses the fuse element and shields it from the elements is known as the fuse body.

- The fuse unit is connected to the electrical circuit by end caps.

- To indicate when a fuse has blown, many contemporary fuse systems come equipped with an indicator.

Fuse Units Brand

- Cooper Bussmann

- Eaton

- General Electric (GE)

- Littelfuse

- Schneider Electric

- Siemens

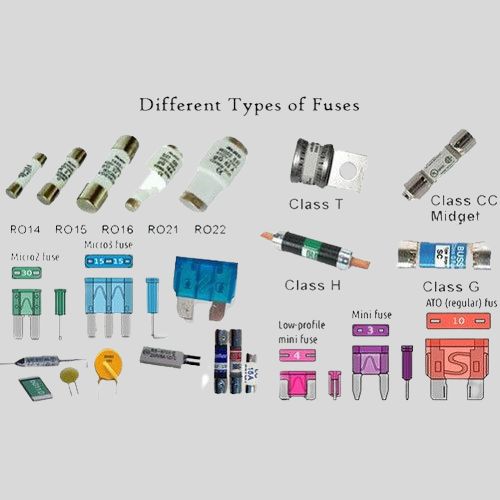

Types of Fuse Units

There are several varieties of fuse units, each intended for a particular usage and setting. The most prevalent kinds are as follows:

Cartridge Fuses:

High currents can be handled with cylindrical cartridge fuses. They are available in a range of sizes and ratings and are usually utilised in industrial settings. Transformers, motor circuits, and power distribution systems all have these fuses.

Blade Fuses:

Blade fuses, which are rectangular and have metal blades that fit straight into the fuse holder, are frequently employed in automobile applications. They come in a variety of sizes and are simple to replace.

Resettable Fuses:

These devices, also referred to as PTC (positive temperature coefficient) fuses, have the ability to self-reset following an overcurrent event. Because of their dependability and ease, they are being utilised in electronic gadgets more and more.

Glass Tube Fuses:

Users can view the fuse element since these fuses are enclosed in a glass tube. They are frequently seen in lower-voltage devices like home appliances.

Applications of Fuse Units

Fuse units are essential to many different industries and applications:

Power Distribution:

Fuse units shield feeders and transformers from overcurrent situations in electrical power distribution networks. They guarantee that system flaws are promptly isolated, reducing damage and downtime.

Industrial Equipment:

Fuse units protect control circuits, motors, and generators in industrial applications. They guarantee operating safety and aid in preserving the integrity of the equipment.

Residential Applications:

Fuse units guard against short circuits and overloads in residential circuits. They serve as a first line of defence against electrical hazards and are frequently seen in electrical panels.

Automotive Systems:

Fuse units in cars safeguard a variety of electrical systems, such as power windows, radios, and lighting. They make sure that any flaws do not result in electrical fires or system malfunctions.

Importance of Fuse Units in Power and Automation

Safety:

A fuse unit is main objective is to increase safety. They shield workers and equipment from possible risks by cutting off the current flow when there is an overcurrent.

Equipment Protection:

Fuse units terminate the circuit when a fault occurs, protecting expensive electrical equipment from harm. This protection lowers maintenance costs and increases the longevity of machinery.

System Reliability:

Electrical systems can function more dependably when fuse units are installed. They lessen unplanned downtime and contribute to consistent operation by preventing failures.

Compliance with Regulations:

Organisations can better adhere to electrical safety requirements and regulations by using the right fuse units. Maintaining safe working conditions and avoiding fines depend on this compliance.

Selecting the Right Fuse Unit

Take into account the following elements when selecting a fuse unit for your application:

Current Rating:

Choose a fuse unit whose current rating corresponds to the needs of your circuit. Underrated fuses may blow too frequently, while overrated fuses might not guard against malfunctions.

Voltage Rating:

Make that your application’s voltage can be handled by the fuse unit. Inadequate protection or fuse failure may result from an improper voltage rating.

Type of Load:

The choice of fuse unit may be influenced by the resistive, inductive, or capacitive loads. Choosing the right type will be made easier if you understand your load characteristics.

Environmental Conditions:

Take into account the operating environment of the fuse unit. Fuse units that can withstand high temperatures, dust, or moisture may be needed for specific applications.

Fuse units are essential components of electrical systems in a variety of sectors, as we at Rudra Power & Automation are aware. You may improve safety, dependability, and efficiency in your operations by making well-informed decisions by being aware of their types, functions, and applications. Investing in the appropriate fuse technology is crucial for safeguarding your equipment and guaranteeing safe operation, regardless of whether you are wanting to replace an outdated fuse unit or create a new electrical system.

Please get in touch with us if you need help choosing the appropriate fuse units for your particular requirements or if you have any questions. Our team of professionals is here to assist you in identifying the best solutions for your automation and power-related problems.