Unlocking the Power of Automation with Modicon PLCs: A Comprehensive Guide

Introduction

Selecting the appropriate control system is essential for improving operational efficiency, cutting expenses, and guaranteeing long-term sustainability in the constantly changing field of industrial automation. Schneider Electric’s Modicon PLCs are unique among the industry leaders in programmable logic controllers (PLCs) due to their scalability, flexibility, and dependability. Advanced automation solutions are our specialty at Rudra Power & Automation, and Modicon PLCs are at the forefront of the goods we suggest to our customers.

This post will explain Modicon PLCs, their main characteristics, advantages, and uses, as well as why they are a great option for companies trying to maximize their automation systems.

What Are Modicon PLCs?

Schneider Electric, a pioneer in energy management and automation solutions worldwide, created the programmable logic controllers known as Modicon PLCs. Since their 1968 debut, Modicon PLCs have been at the forefront of industrial automation development, providing cutting-edge solutions for machinery automation, process control, and system monitoring.

The Modicon PLC line is intended to give industrial machinery and systems control, monitoring, and data processing capabilities. These PLCs are intended for application in a variety of sectors, including building automation, water treatment, manufacturing, and energy.

Because of their excellent performance, scalability, and intuitive programming environments, Modicon PLCs are a great option for businesses wishing to integrate cutting-edge automation technologies and optimize their processes.

Key Features of Modicon PLCs

Scalability and Flexibility:

The scalability of Modicon PLCs is one of its best qualities. Modicon PLCs provide versatility in terms of size, input/output (I/O) capabilities, and processing capacity, regardless of the size of the system or the automated project. Because of its scalability, they can be used in a variety of industries, including as the production of food and beverages, water treatment, oil and gas, and automobiles.

In order to accommodate changing needs, Modicon PLCs can be readily extended by adding additional I/O modules or communication interfaces, providing long-term flexibility as your company expands.

Modular Design:

Because of the modular design of Modicon PLCs, users can choose from a large selection of CPU processors, I/O modules, and communication choices to personalize their systems. Because the system is modular, users only need to buy the parts they need, which lowers the initial investment costs while maintaining the system’s flexibility for future growth.

High Performance and Processing Speed:

Modicon PLCs have strong processors that can manage intricate automation applications, and they are designed for high-performance activities. Because of their quick processing rates, these PLCs provide real-time control and monitoring of crucial industrial operations. Modicon PLCs guarantee effective data processing, enabling prompt decision-making and little downtime whether you are in charge of an assembly line or a process facility.

Seamless Communication and Integration:

The ability of Modicon PLCs to communicate is another important characteristic. Numerous industrial communication protocols, including as Ethernet/IP, Modbus TCP, PROFINET, and CANopen, are supported by them. This makes it simple to integrate with other networks, systems, and devices in your building, resulting in a smooth information flow throughout your whole automation ecosystem.

Modicon PLCs are a great option for companies with mixed automation systems since they support open protocols, which make it simple to interface with equipment from other manufacturers.

Advanced Diagnostic and Monitoring Features:

Modicon PLCs have sophisticated monitoring and diagnostic capabilities that assist companies in spotting problems before they become serious ones. Predictive maintenance is made possible by these diagnostic skills, which lower downtime and avoid expensive equipment failures. To further reduce downtime, Modicon PLCs also provide remote monitoring, which enables engineers and operators to view real-time system data and troubleshoot problems from a distance.

User-Friendly Programming Environment:

SoMachine software and Schneider Electric’s EcoStruxureTM Control Expert (previously Unity Pro) make it simple to program and configure Modicon PLCs. These user-friendly software platforms give users access to an integrated programming environment for managing I/O modules, developing control systems, and resolving problems. Ladder Logic, Function Block Diagram (FBD), and Structured Text are just a few of the programming languages that EcoStruxureTM Control Expert offers, allowing engineers to utilize the one that best fits their needs.

Benefits of Modicon PLCs

Cost Efficiency:

Modicon PLCs combine cost-effective solutions with superior performance to deliver exceptional value for the money. Because of their modular architecture and scalability, companies only pay for the parts they require, making them a cost-effective choice for automation projects of all sizes. Their lengthy lifespan and minimal maintenance needs also contribute to a gradual decrease in the overall cost of ownership.

Improved Operational Efficiency:

By facilitating quicker decision-making, decreasing downtime, and guaranteeing ongoing monitoring of vital systems, Modicon PLCs increase operational efficiency. These PLCs assist companies in increasing productivity and decreasing human error by automating repetitive operations and streamlining manufacturing processes.

Enhanced Safety:

In industrial settings, safety is a top priority. Modicon PLCs can help companies adhere to international safety standards like ISO 13849 and IEC 61508 by directly integrating safety elements into the control system. Features like emergency stop features and safety relays lower the chance of accidents and increase the general safety of your operations by protecting both personnel and equipment.

Future-Proof Technology:

Future-proofing is a key consideration in the design of Modicon PLCs. Modicon PLCs help businesses stay ahead of the curve by making it simple to connect new technologies, like cloud-based systems and Industrial Internet of Things (IIoT) devices. The PLCs are an excellent option for businesses wishing to adopt the newest wave of automation and digitization since they are completely compatible with Industry 4.0 systems.

Global Support and Expertise:

Modicon PLCs enjoy comprehensive customer support, training, and technical assistance as a member of Schneider Electric’s global network. Schneider Electric makes sure that companies have access to the tools they need to maintain and improve their automation systems by maintaining offices and service centers across the globe.

Applications of Modicon PLCs

Because of its adaptability, Modicon PLCs can be utilized in a wide range of sectors and applications. The following are some important applications where Modicon PLCs are frequently used:

Manufacturing Automation:

Modicon PLCs are extensively utilized in the industrial industry to automate production lines, manage robotic systems, and keep an eye on the functioning of machinery. From basic machine control to intricate manufacturing procedures, these PLCs can manage it all, guaranteeing that goods are produced with extreme accuracy and reliability.

Process Control:

Process sectors like oil and gas, chemical manufacturing, pharmaceutical manufacturing, and food and beverage manufacturing make substantial use of Modicon PLCs. They are employed to ensure that processes function smoothly and effectively by monitoring and controlling vital factors including temperature, pressure, flow, and level in real-time.

Water Treatment and Infrastructure:

Modicon PLCs are essential for managing pumps, valves, and filtration systems in water and wastewater treatment facilities. They optimize energy use and reduce operating expenses while assisting in maintaining water quality.

Energy Management:

Modicon PLCs are extensively utilized in energy management systems to track and maximize energy use in sectors like industrial facilities, building automation, and power generating. By automating HVAC, lighting, and other energy-consuming systems, they assist companies in lowering energy expenses and enhancing sustainability.

Building Automation:

Lighting, HVAC, security, and other systems are all managed by Modicon PLCs in building automation systems. Businesses can increase building security, comfort, and energy efficiency by automating these systems.

Why Choose Modicon PLCs?

Modicon PLCs provide the ideal balance of scalability, performance, and dependability. Modicon PLCs offer the adaptability and control required to maximize your operations, whether you’re controlling a complicated industrial process or automating a basic equipment. Modicon PLCs are a crucial component of the automation solutions that Rudra Power & Automation specializes in providing, which include the newest and most efficient technologies.

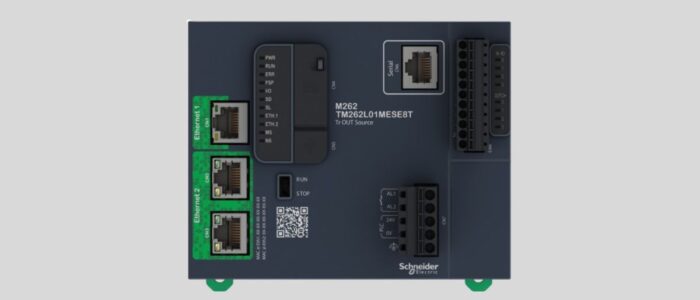

Schneider Modicon PLCs

Businesses may cut expenses, increase safety, streamline operations, and maintain their competitiveness in the fast-paced industrial environment of today by using Modicon PLCs. For companies wishing to future-proof their automation systems, Modicon PLCs are the ideal option due to their extensive feature set, simplicity of use, and scalability.

To find out more about how Modicon PLCs can improve your industrial automation systems and assist you in reaching your business objectives, get in touch with Rudra Power & Automation right now.