Relay

Relays: The Backbone of Electrical Control Systems

Relays are essential parts of electrical and electronic circuits because they act as switches, allowing low power signals to operate high power devices. Relays are essential components of automation and control systems, ranging from household appliances to large industrial machines. The foundations of relays, their varieties, uses, and advantages, as well as how they are influencing electrical engineering going forward, will all be covered in this article.

What is a Relay?

Relays are electrical or electromechanical switches that respond to input signals by opening and closing circuits. A relay links or disconnects higher voltage or current circuits based on a mechanism it activates in response to a low-voltage signal. Relays can now manage heavier loads without having to physically engage with the high-power circuit.

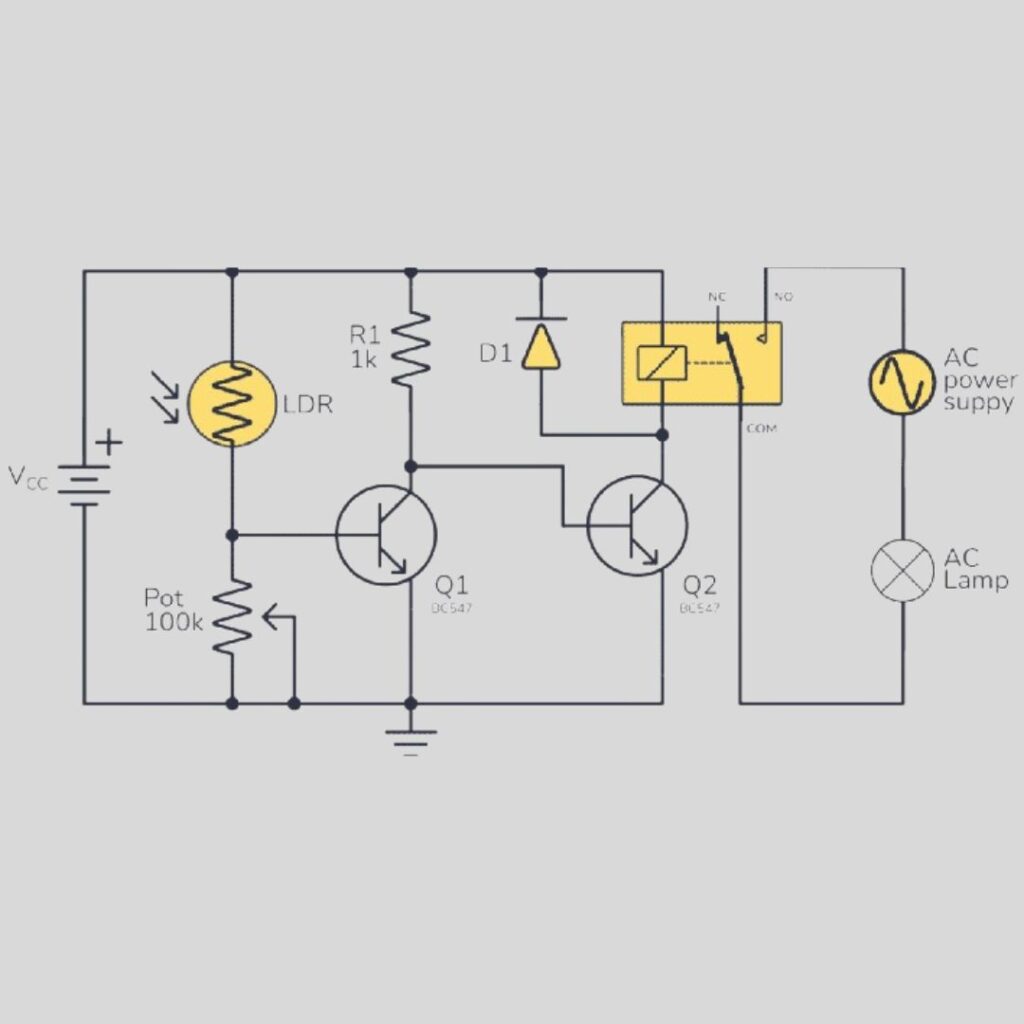

How Does a Relay Work?

An electromagnet, an armature that is spring-loaded, and a series of contacts are required for the fundamental functioning of a relay. This is how it operates:

Electromagnet Activation:

The armature is drawn to the low-voltage current flowing through the relay’s coil because of the magnetic field it creates.

Contact Movement:

Depending on the type of relay, the armature movement opens or shuts the contacts. By doing this, the regulated circuit is connected or disconnected.

Return Mechanism:

Resetting the relay occurs when the input signal is eliminated, causing the magnetic field to collapse and the armature to return to its initial position via the spring mechanism.

Relay Brand

- Finder

- Omron

- Schneider

- TE Connectivity

Types of Relays

There are several varieties of relays, and each is intended for a particular use. These are a few of the most typical kinds:

Electromechanical Relays (EMR):

These are the conventional relays that function by means of electromagnetic coils. Because of their dependability and simplicity, they are frequently employed in many different applications.

Solid-State Relays (SSR):

SSRs employ semiconductor devices instead of moving parts to switch circuits, in contrast to EMRs. As a result, there is reduced noise, longer life, and quicker switching times.

Reed Relays:

These are glass tubes that are sealed around two magnetic rods. The reeds unite to complete the circuit when a magnetic field is introduced. Reed relays are renowned for their quick switching speeds and small size.

Time Delay Relays:

Before a circuit is activated or deactivated, these relays add a delay. In applications where timing is crucial, they are frequently utilised.

Latching Relays:

After being triggered, these relays hold their position; a second signal is needed to modify their state. Since they do not need electricity to stay in place, this attribute makes them valuable in applications where power conservation is crucial.

Applications of Relays

Relays are used in many different industries and for a variety of purposes. Here are a few noteworthy instances:

- Automotive Industry: For the control of lights, motors, and other electrical components in cars, relays are indispensable. They enable low-power switches to operate high-current loads while also aiding in their management.

- Automation in Industry: Relays are used in manufacturing and process control to automate machines and equipment. They improve efficiency and safety by making it possible to operate large machinery with only a few basic control signals.

- Home Appliances: Relays are used in a lot of domestic appliances, like washing machines, refrigerators, and air conditioning systems, to regulate motors and heating elements and ensure dependable performance.

- Telecommunications: To ensure dependable communication, relays are employed in telecommunication systems to manage connections and switch signals.

- Security Systems: When a security breach is discovered, relays in alarm systems can trigger sirens or other alert devices, adding a crucial layer of defence.

- Power Management: In order to operate circuit breakers and manage electrical loads in order to prevent overloads, relays are essential components of power distribution systems.

Advantages of Using Relays

Relays are a preferred option in many applications because of their many benefits:

- Control of High Power Loads: They are perfect for automation and control systems because they allow low-power devices to control high-power circuits.

- Versatility: Relays come in a variety of forms and can be customised to match the needs of a particular application, be it switching, latching, or timing.

- Dependability: Electromechanical relays are dependable for continuous usage because of their lengthy operational life and capacity to withstand a large number of switching cycles. Cost-Effectiveness: Relays are typically inexpensive parts that offer a cost-effective way to regulate electrical circuits.

- Electrical isolation: It is provided by relays between the load circuit and the control circuit, shielding delicate components from high currents and voltages.

Choosing the Right Relay

When choosing a relay for a particular use, take into account the following aspects:

- Load Requirements: To make sure the relay can manage the electrical needs, find out the load’s voltage and current ratings.

- Type of Relay: Select the type of relay you need by considering the speed, size, and environmental factors of the application. Solid-state, electromechanical, and other varieties are available.

- Control Signal: Verify that the relay can be turned on using the available control signal, which could be an AC or DC input type or a low-voltage signal.

- Switching Configuration: Take into account how many throws and poles are needed for the application. A double-pole double-throw (DPDT) relay, on the other hand, can control two different circuits at once, but a single-pole double-throw (SPDT) relay can only switch between two circuits.

- Environmental Conditions: Evaluate the temperature, humidity, and possibility of dust or moisture exposure in the operational area. Certain relays may have protective casings and are made to withstand hostile environments.

- Reaction Time: Determine how fast the programme needs to move between states. While some applications can handle slower response times, others could need fast switching.

- Size and Mounting: Verify that the relay can be mounted correctly in the application and that it will fit inside the available area.

- Cost and Availability: Take into account the relay’s availability and cost. Although certain specialised relays might have more sophisticated capabilities, they might also cost more or be more difficult to find.