Stepper Motor Drives

Understanding Stepper Motor Drives: Precision in Motion Control

Because stepper motor drives can produce exact movement without the need for feedback systems, they are vital parts of the automation and motion control industries. This article explores the principles, uses, advantages, and ways that stepper motor drives improve productivity across a range of sectors.

What are stepper motor drives?

Stepper motor’s operations are managed by stepper motor drives, which transforms digital pulses into mechanical motion. Stepper motors move in distinct steps as opposed to regular motors, which rotate continuously, enabling precise positioning. Applications needing high precision and repeatability can choose the stepper motor drive because it can translate controller commands into accurate movements.

Strepper Motor Drives Brand

- Applied Motion Products

- DROK

- Leadshine

- Microchip Technology

- Oriental Moto

- StepperOnline

Key Components of Stepper Motor Drives

Stepper Motor:

Stepper motors, the system’s central component, are made up of several coils that produce magnetic fields. Rotation can be achieved in predetermined steps or increments by interacting with permanent magnets.

Controller:

To ascertain the motor’s position, speed, and direction, the controller transmits digital pulses to the drive. Either a motion controller or a microcontroller can be used.

Power Supply:

The electrical energy required to run the motor and drive system effectively is supplied by a power supply.

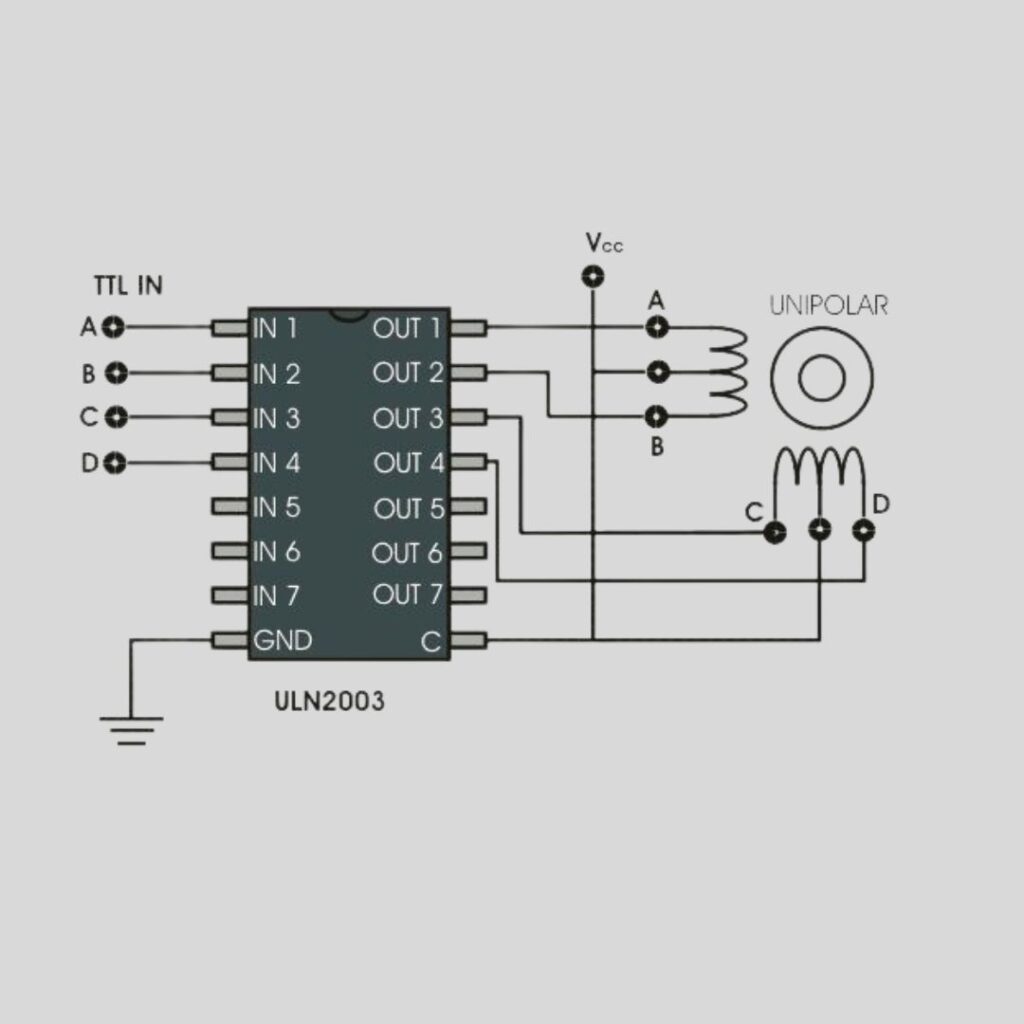

Driver Circuit:

Accurate control over movement is made possible by the driver circuit, which converts the control signals into current pulses that energise the motor coils.

Applications of Stepper Motor Drives

Stepper motor drives are adaptable and have uses in a range of industries because of their special qualities:

3D Printing

Stepper motors are utilised in 3D printers to accurately regulate the movement of the build platform and print head. This accuracy permits complex designs and guarantees prints of the highest calibre.

CNC Machines

Stepper motor drives are used by Computer Numerical Control (CNC) machines to precisely position cutting tools. This degree of control lowers material waste and improves machining precision.

Robotics

Stepper motors are used in robotics to precisely operate robotic arms and other devices. Their precision in maintaining locations makes them perfect for jobs like welding and assembling.

Textile Machinery

Stepper motor drives are widely utilised in textile manufacturing to regulate the movement of fabrics and sewing processes. Their exact control makes cloth production more consistent and of higher quality.

Medical Devices

Stepper motor drives offer the accuracy required for precise positioning and operation in medical equipment, such as MRI machines and infusion pumps, guaranteeing patient safety and device dependability.

Benefits of Using Stepper Motor Drives

The advantages of implementing stepper motor drives in automation systems are significant:

High Precision:

Stepper motors are perfect for applications where accuracy is crucial because they can achieve exact positioning with great repeatability.

Simple Control:

Compared to other motor types, stepper motors require less complex control systems since they can be operated using straightforward digital signals.

Cost-Effective:

Stepper motor drives are a more economical option for many applications since they are often less expensive than servo systems.

Open-Loop Control:

Stepper motors are more cost-effective and easier to run in open-loop settings than servo motors, which necessitate feedback devices. This makes system design simpler.

Robustness:

Because stepper motors are renowned for their dependability and robustness, they are appropriate for harsh industrial settings.