Servo Motor Drives

Knowing Servo Motor Drives: An Essential Automation Component

Servo motor drives, which offer exact control over acceleration, velocity, and angular or linear position, are crucial parts of contemporary automation and control systems. Servo motor drives are essential for improving performance, precision, and efficiency in a variety of applications, including robots and CNC machines. This article will examine the foundations of servo motor drives, their uses, and the advantages they provide across a range of sectors.

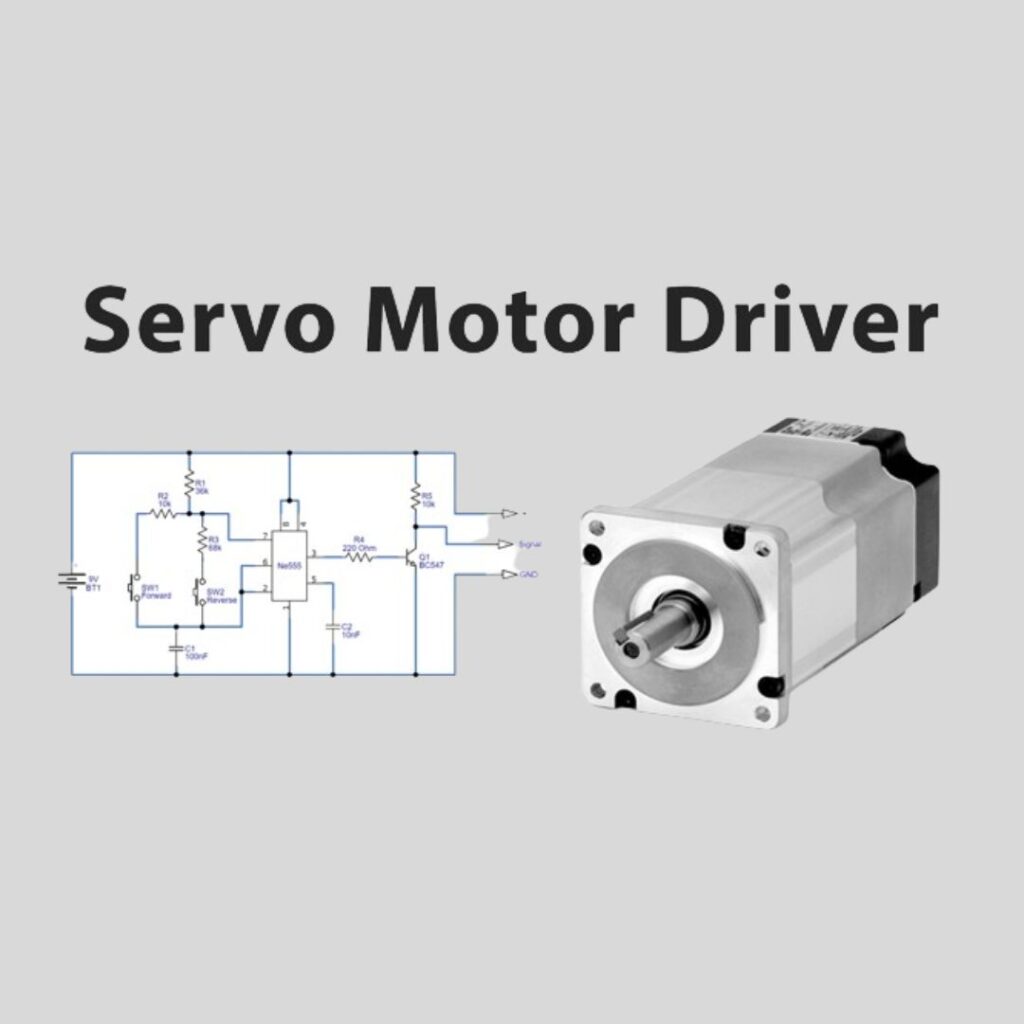

What is a Servo Motor Drives?

Modern automation and control systems require servo motor drives because they offer exact control over angular or linear position, velocity, and An electrical device that regulates a servo motor’s position and speed is called a servo motor drive. It ensures exact control over motion by interpreting commands from a control system and modifying the motor’s functioning accordingly. In contrast to ordinary motors, which run continuously, servo motors can change their position and speed in response to system feedback.quickening. Servo motor drives are essential for improving performance, precision, and efficiency in a variety of applications, including robots and CNC machines. This article will examine the foundations of servo motor drives, their uses, and the advantages they provide.

Components of Servo Motor Drives

Servo Motor:

The servo motor, which is at the centre of the system, transforms electrical energy into mechanical energy. A brushless, AC, or DC motor may be used, depending on the intended use.

Feedback Device:

This device, which is usually an encoder or resolver, gives the drive real-time information about the position, speed, and direction of the motor so that it can make the appropriate adjustments.

Controller:

The controller dictates the necessary movement and speed by processing the input commands and sending signals to the motor drive.

Power Supply:

The electrical energy required for the motor and drive system to function effectively is supplied by a power supply.

Servo Motor Drives Brand

- Fuji

- Omron

- Schneider

- Siemens

Applications of Servo Motor Drives

Servo motor drives are used across various industries due to their versatility and precision.

Robotics:

Servo motor drives are used in robotics to precisely control robotic arms and other systems. For jobs like material handling, welding, and assembling, they provide precise positioning and complex movements.

CNC Machining:

Servo motor drives play a major role in the accurate positioning and movement of cutting tools in Computer Numerical Control (CNC) equipment. Servo drives’ accuracy guarantees precision machining while cutting waste.

Printing Machines:

Servo motor drives are utilised in the printing industry to maintain constant print quality and synchronise print heads. High-resolution outputs can be obtained with their exact control.

Medical Equipment:

In medical technologies like robotic surgery systems and MRI machines, where precise positioning and movements are crucial for patient safety and diagnostic accuracy, servo drives play a vital role.

Benefits of Using Servo Motor Drives

The advantages of implementing servo motor drives in automation systems are significant:

High Precision:

Servo motor drives are perfect for applications demanding tight tolerances because they offer remarkable position control accuracy.

Improved Efficiency:

Servo drives improve machine efficiency by maximising torque and speed, which lowers energy usage and operating expenses.

Fast Response Times:

Servo motor drives ensure quick adjustments and better performance by responding swiftly to changes in control signals.

Enhanced Reliability:

Servo drives can identify abnormalities and make adjustments based on built-in feedback mechanisms, leading to a more dependable and steady operation.

Flexibility:

Servo motor drives are simply customisable and adaptable to diverse applications by being able to be integrated into a variety of systems.